In the world of construction, agriculture, and landscaping, few machines are able to match the versatility and utility of the backhoe loader. From digging trenches to lifting heavy loads, these workhorses of the job site can quickly and efficiently accomplish the challenge at hand.

Yet, behind their seemingly simple design lies a complex wealth of functionality and adaptability. It can be a challenge to recognize the full capabilities of the backhoe loader.

In this complete guide, we take a look at the critical components of a backhoe loader, its versatility, and its value compared to other construction tools.

What is a Backhoe Loader?

Backhoe loaders (commonly called Tractor Loader Backhoes)are heavy-duty construction equipment built on a tractor-like base. An excavator shovel (loader) is mounted to the front of the vehicle, and a digging bucket (backhoe) is mounted at the rear.

The compact but powerful backhoe loader excels at landscaping jobs, such as digging up trees and moving large rocks, boulders, and gravel.

Backhoe loaders and excavators share many similarities. Both machines have landscape digging capabilities and come with an articulated arm with a bucket at the end. The key differentiator here is that backhoes are smaller in size and have a loader bucket at the front.

Key Components of a Backhoe Loader

Any general all-purpose construction equipment must be able to perform several tasks efficiently and effectively. The three key components of a backhoe loader have solidified its position as the jack of all trades in the construction industry.

The following are the three main components of backhoe loaders.

- Tractors

- Loaders

- Backhoes

1. The Tractor Section

The tractor base of backhoe loaders shares the same chassis as a regular farm tractor, with two big tires at the rear and two small ones at the front.

It also has an elevated seat and steering wheel. The driver’s seat is protected by a robust cabin with thick windows that keep rocks and other debris away.

2. The Loader Section

The loader bucket is attached to an articulating boom arm mounted on the tractor hood. It is commonly used to move heavy objects around the construction site.

While the loader bucket can be used to remove ground material capabilities, its small size limits the digging depth.

A better use for the loader is to fill in large holes by pushing loose dirt and smoothing the top.

3. The Backhoe Section

Finally, we have our primary tool, the backhoe. It is mounted to the rear of the tractor with a three-joint boom arm.

A joint at the tractor base, another at the bucket, and a third in the middle. Some models of the backhoe loader also have an extendable arm for additional coverage.

It is the most versatile component of the machine, capable of digging up hard ground, compacting soft soil, and lifting heavy loads.

4. The Optional Outriggers (Stabilizer Legs)

The backhoe is already one of the most capable heavy machinery available on the market. With additional backhoe attachments, its versatility is further increased. One such attachment is a pair of stabilizer legs.

Stabilizer legs are hydraulic-driven support beams that anchor the tractor to the ground, keeping the tires from slipping. Stabilizers are also often used for additional leverage when picking up or moving heavy equipment.

We discuss the various types of backhoe attachments later in this article.

Applications of Backhoe Loaders

Backhoes are versatile machines that can be deployed on a number of tasks on the construction site. Here are just some of its uses.

- Agriculture: Excellent at digging trenches, clearing cropland after crop harvest, planting trees, tilling the soil, etc.

- Construction: Covers all types of site work, including excavating ground, digging trenches for building foundations, moving heavy materials, etc.

- Demolition: Generally used for cleanup work at demolition sites, such as breaking large rocks and debris, moving waste and rubble, etc.

- Landscaping: Mostly involves simple ground work such as leveling, digging, and clearing.

- Mining: Backhoes are used for material excavation from tight spots and transferring them to larger dump trucks.

- Road Work: Backhoes can be used for all types of road work and maintenance, such as filling in potholes, snow removal, and road repairs.

Every Type of Backhoe Loader Attachment

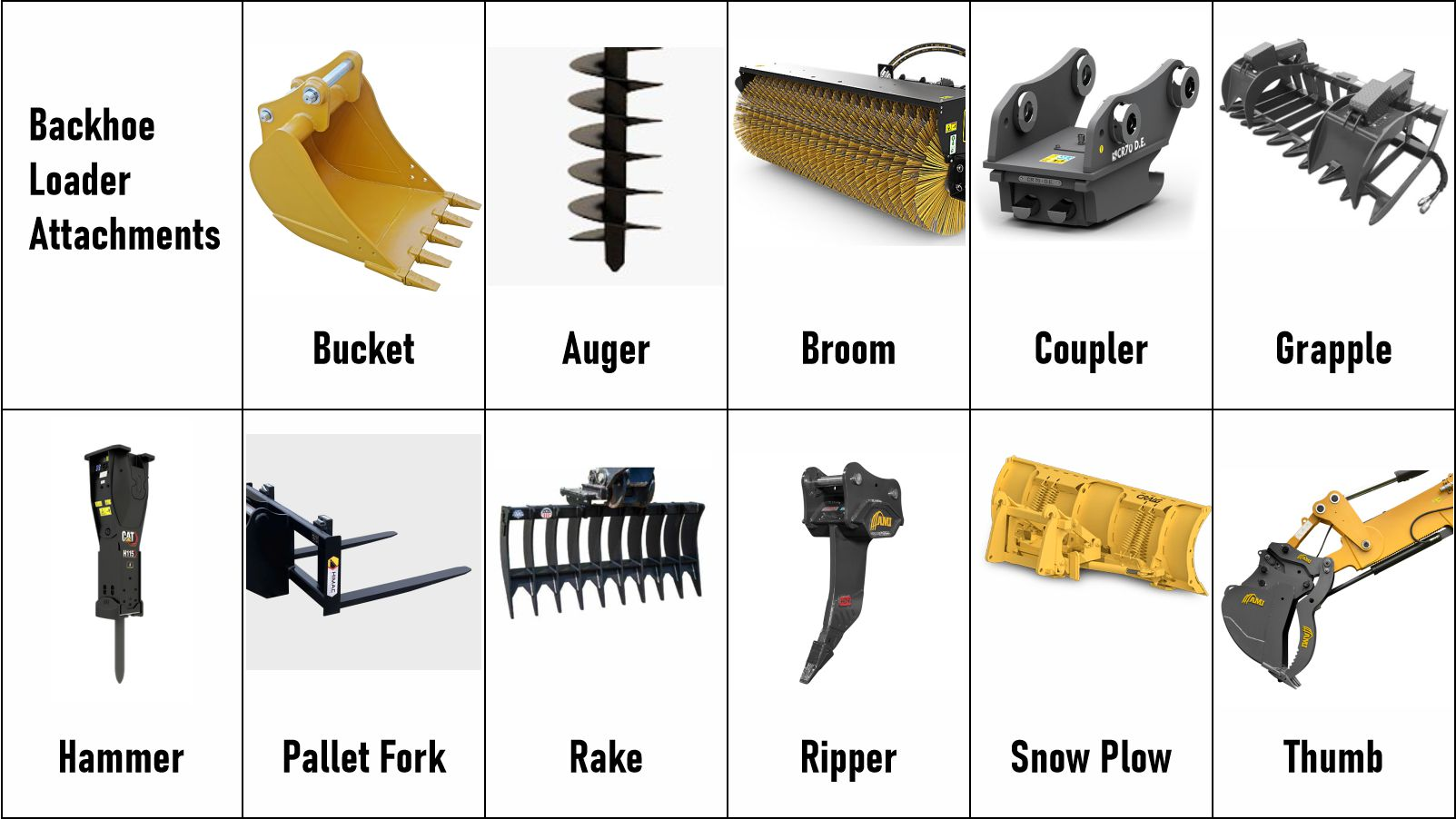

Backhoe loaders come with several handy tools that can be equipped at the tip of the backhoe for additional functionality.

Here is a brief breakdown of every backhoe attachment.

1. Bucket

The bucket is a standard attachment used for digging, lifting and loading materials. Bucket attachments come in various sizes and configurations for different tasks.

2. Auger

An auger is a drill-like spiral tool designed for drilling holes in the ground. It is commonly used for tasks like planting trees, installing fence posts or creating foundations.

3. Broom

A broom is a large horizontal tool that has bristles at the end. It is used for sweeping and cleaning surfaces, such as roads, pavements, or parking lots. The most common broom design has a cylindrical shape and spins for better sweeping performance.

4. Coupler

A coupler is a tool holder that allows the operator to quickly and easily swap between attachments from the comfort of their cabin without needing to manually disconnect and reconnect hydraulic hoses.

5. Grapple

Grapples are teeth-like clamp attachments that are used for grabbing and lifting bulky or irregularly shaped objects, such as logs, rocks, or debris.

6. Hammer

The hammer attachment is a hydraulic jackhammer that is used for breaking up asphalt and hard rocks. The controlling hydraulic system determines its power output.

7. Pallet Fork

Pallet fork attachments give your backhoe temporary forklift functionality. They are used for lifting and moving heavy materials, such as bags of cement, stacks of lumber, or crates.

8. Rake

A rake attachment is a large set of metal spikes that are installed close to ground level. It is useful for agricultural work such as leveling and smoothing uneven surfaces, preparing soil for planting, or clearing debris.

9. Ripper

The ripper attachment is one of the most odd-looking tools. It looks like a large shark tooth or a hawk talon and is used for breaking up compacted soil, rock, or pavement. Despite its odd shape, the ripper can prove very useful at a job site.

10. Snowplow

A snow plow attachment has a large rectangular profile with a concave interior. As the backhoe loader moves through the streets, the plow scrapes up the heavy snow and pushes it to the sides. Although it is less useful at construction sites, its functionality in those snowy winters makes it a great investment.

The plow attachment is one of the best tools for snow removal.

11. Thumb

A thumb attachment looks like a dinosaur head with big, sturdy jaws. It’s called a thumb because it enables the backhoe loader to perform more complex tasks. Thumb attachments have excellent lifting capacity and transform your backhoe loader into a mini excavator.

It is more versatile than a bucket attachment but has a much lower internal volume.

Choosing the Right Backhoe Loader

Job sites are often full of challenges, be it rough terrain, bad weather, or a remote location. A good backhoe loader should overcome most, if not all, of these challenges.

Here are five key factors to consider when buying a backhoe.

1. Lifting Capacity

Take a thorough look at the backhoe specs and find out the machine’s maximum lift capacity and the amount of weight that can be carried in the backhoe bucket. You should also know the load-bearing capabilities of the loader arm.

Ensure it can handle the materials and loads typical of your job sites. Consider factors such as the weight of the materials, the height to which they need to be lifted, and any safety regulations regarding lifting capacities.

2. Attachment Options

Look for manufacturers that also offer a variety of attachment options for your backhoe loader. These attachments can be quite expensive. Be sure to thoroughly examine your workload before investing.

Between the backhoe and loader bucket, your machine can cover most of the workload. For many businesses, the investment in backhoe attachments is simply not worth the price.

3. Machine Size

The size of the backhoe tractor is another big factor. Larger models have better lift capacity and have more digging power. However, if your construction site is based in an urban area, the maneuverability of a smaller, more compact machine should be prioritized.

4. Shipping Costs

Additional costs are always associated with buying heavy equipment. Packing and shipping costs should also be taken into account when finalizing your budget. Overseas shipment, in particular, can be quite expensive.

5. New vs. Used Backhoe

Buying a used backhoe loader is always an option for those up-and-coming businesses. Used models have a fraction of the price of a new backhoe. Like with any used equipment you are trading cost benefit for quality.

Used backhoe loaders might be at the end of their life span and require heavy maintenance before being fully operational. Heavy equipment, like a backhoe, can see over ten years of use before a business decides to upgrade and sell the old one.

Always be careful when getting used equipment, and if possible, try to stick to new machines from reputable sellers.

Backhoe Loader vs. Excavator

Excavators and backhoe loaders share the same working principle, as both machines are adept at digging.

However, when we look at the details, we see that an application-specific machine like an excavator is very different from a backhoe loader.

1. Machine Size

Excavators are generally larger than backhoe loaders and offer more lifting capacity, better-digging depth, and scale from small to large projects.

Contrarily, backhoes are smaller, making it easier for them to maneuver around tight spaces and transport the tractor from one job site to another.

2. Flexibility and Versatility

Large-scale excavation projects prioritize work efficiency (digging capacity) over cost efficiency. Thus, a large, heavy-duty excavator with specialized attachments will always outperform a backhoe loader.

However, if we look at long-term viability, the backhoe loader can accomplish more tasks but at a slower pace.

3. Degree of Freedom

The degree of freedom (DOF) refers to the mobility of a mechanical system. Backhoe loaders have 4-DOF, correlating to the four joints in the boom arm. Meanwhile, Excavators have 5-DOF. They also have four joints in the hydraulic arm, and the entire system sits on top of a rotating platform.

Unlike a backhoe machine, an excavator with stabilizers deployed can still rotate 360 degrees.

FAQs

1. How Much Does a Backhoe Loader Cost?

An entry-level backhoe loader starts at $25,000, with expensive ones easily reaching upwards of $200,000. Always account for shipping costs when you purchase any heavy machinery.

2. Difference Between Loaders and Backhoes?

The backhoe attachment on the rear of a tractor has better range and mobility. Loaders at the front have better lifting capacity.

3. Do Backhoe Loaders Use Hydraulics?

Yes, All backhoe loaders run on a hydraulic system. It results in a higher power output than a mechanical motor and gear system.

Conclusion

Backhoe loaders are a marvel of modern technology and ingenuity. It takes the best parts of modern heavy machines and combines them into a single versatile unit.

The best part about having a backhoe is the flexibility in attachments. A backhoe is a great tool for those small to medium businesses. Very few machines can match the flexibility and versatility of the humble backhoe.

Load Up for Success with Everstar!

Everstar is a titan of the heavy machinery industry. With over a decade of experience manufacturing quality components, we have established ourselves as the go-to brand for all your construction equipment.

Our state-of-the-art backhoe loaders are built to last, complying with all international quality and safety standards, including the ISO9001, CE, and CCC certifications. Everstar offers comprehensive startup and training guidance to all our customers to help them hit the ground running.

Choose a brand that has your best interest at heart. Choose Everstar. Contact Us Now!