Have you ever thought about how essential utilities are obtained such as pipes, gas lines, or even something as simple as a drainage system? This is where trenching comes in. Trenching is imperative in your construction and excavation projects by cutting narrow yet deep channels for installations. It doesn’t matter if you are building a foundation, controlling water flow, or even laying utilities. Trenching makes sure that everything is done safely and efficiently. Ready to explore how it’s done?

1) What Is Trenching?

Trenching is the act of excavating a deep and narrow hole in the ground with the aim of laying water pipes, gas lines, or electrical cables. Think of it as constructing a miniature tunnel underneath the ground for these crucial items to be placed. Trenches are intended to ensure that all utilities are safeguarded and concealed, which allows all the equipment above ground to function properly.

Importance of Trenching

Trenching is one of the most crucial steps of any construction process. It assists in land preparation and contributes to the development of the infrastructure of the country or region that helps in its operation. There may be utility lines or heating system pipes not visible to the eye and trenching ensured there was a place for them. Actually, the USA can boast of more than 1.5 million country miles of pipelines, all thanks to Trenching.

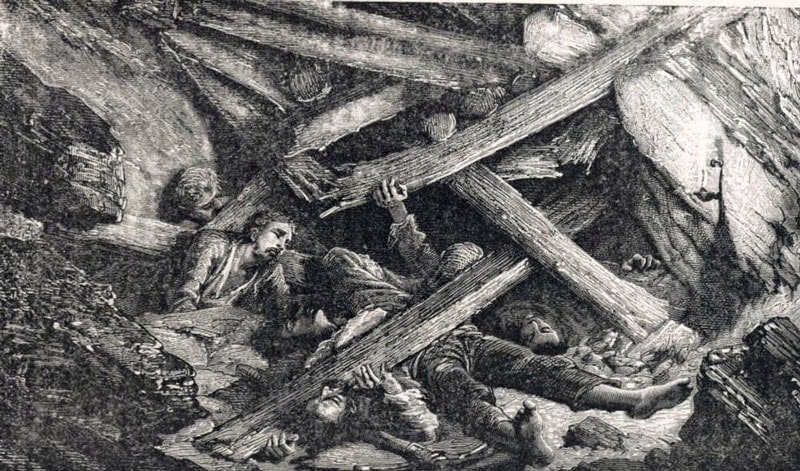

In addition, digging trenches aids in fostering formidable bases for structures, thus ensuring they are intact. In case you wish to erect a residential house or an apartment building, trenching helps prepare the ground’s surface for the foundation that holds everything in place. Moreover, in World War 1 soldiers dug man-made trenches to protect themselves, this is referred to as trench warfare.

2) Trench Construction Techniques

It’s very crucial to know what tools and techniques to use when digging trenches. Let’s have a look at these!

Types of Trenches

- Shallow Trenches (Less Than 6 Feet Deep): This type is typically used for small utility systems such as irrigation, electric, and telephone lines. For shallow trenches, there is less requirement for bracing since they are not excavated deep into the ground. However, proper backfilling is important to protect against erosion.

- Deep Trenches (More Than 10 Feet Deep): This deep trench setting is used for essential structures like sewage systems, water mains, and gas pipelines. There is an increased chance of a cave-in with these trenches than the rest.

- Wide Trenches: As their name indicates, these trenches are wider than normal ones and are used in extensive activities such as road building, large foundations or big-diameter pipes. More often than not, wide trenches tend to require greater excavating and set-up work to keep the walls from collapsing.

Keep in mind that not all excavations are wide as slit trenches are narrow compared to all other types of trenches. They are only a few inches wide so you can use them for placing small electric cables or telephone wires.

Excavation Methods

i) Manual Excavation: You may want to consider manual tools when working on small or fine projects that need delicate tackling like the area around pipelines or buildings. Manual trenching is the slowest of methods, yet the most labor-intensive. It is also practical for crops that require little digging as well as for areas with tight restrictions or shallow depth.

ii) Mechanical Excavation: Heavy machinery is essential for digging deeper and faster on larger projects. Here are some machines you might find:

- Backhoes: These machines are quite flexible in their applications, having a loader at the front and a digging bucket at the rear. Suitable for digging mid-depth trenches.

- Excavators: Used for deep trenching in expansive construction sites, these machines are more powerful than backhoes and larger in size.

- Trenchers: These machines are made specifically to dig trenches and do so with great speed. Wheel and chain trenchers are used to cut through various soil and rock types.

Backhoe Loaders in Trenching

A backhoe loader is easier to operate than other machines and remains one of the most popular machines used for trenching. Its head is able to scoop, while the tail can load, allowing it to transport and dig materials in the most efficient way possible.

- Speed and Efficiency: Instead of spending hours digging trenches by hand, with a backhoe you can complete the task in minutes.

- Versatility: Backhoe loaders have multiple uses depending on one’s need. Weavers best perform in a construction project, typically roads and plumbing, since they can function in a range of soil conditions, be it gravel, clay, or even compacted dirt.

- Safety: Using a backhoe reduces worker fatigue and the risk of injuries. Excavating manually can be dangerous, especially in deep trenches where falls or cave-ins are serious hazards.

- Cost-Effective: A backhoe loader requires fuel and maintenance costs, yet actually considered cost-effective. This is because the reduced labor and increased productivity that result from using a backhoe far outweigh the costs of upkeep.

3) Safety Considerations in Trenching

Let us explore some of the safety rules, potential risks, and measures that can be taken to ensure the safety of individuals during trenching. Remember, non-compliance can result in adverse consequences.

Trench Protection Measures

Specific trenching measures have been designed to provide maximum occupational safety. For instance, OSHA is famous for its extraordinarily strict rule enforcement, especially regarding the USA trenching guidelines. Here is some of this information that might be useful to you:

- Every trench deeper than five feet is mandated to have a protective device like trench boxes or shoring; this is to cater to the possibility of a cave-in. Before any work begins, you need to ensure that this is in place and operational.

- Where a trench is deeper than twenty feet, the safety system should be drawn up by a professional engineer.

- Workers must be enabled to safely descend or ascend from trenches that overshoot four feet in depth. This could be through the use of ramps or ladders. Having a safe method of access and knowing the exact location aids in your speedy exit if the situation calls for it.

- Prior to excavating, underground utility lines have to be marked out in order to avoid hazardous situations. This critical step should never be overlooked – safety is paramount!

Common trenching Hazards

Cave-ins (Greatest Risk in Trenching): A trench collapse can leave people buried alive beneath several tons of soil and other paraphernalia. One cubic yard of soil often weighs in excess of three thousand pounds, equivalent to a small car!

Falling Loads: When machines like backhoes shift and put dirt or other materials adjacent to a trench, workers standing below are at risk of suffering injuries from decaying fragments. Be aware, this could result in very serious injuries.

Dangerous Atmospheres: Some trenches, primarily the deeper ones, may contain poisonous gases or maybe oxygen-deficient. If a worker does not analyze the air before stepping in, he can hyperventilate or even choke to death. As a rule of thumb, always check the quality of air before entering a space.

Falling and Slipping: Employees can slip inside or outside the trenched area. Deep trenches pose a threat since falling can lead to severe injuries. Always ensure access is safe like with ladders and ramps.

Water Trapping: Water penetrating the walls would weaken the walls and pose the risk of a collapse. Regularly check for water collection and act quickly to pump the water out in case it’s needed.

Safety Practices

You can make trenching safer by following key best practices. Here’s how you can protect workers and prevent accidents:

i) Use Protective Systems: Never step foot in an uncovered trench. For every trench, use Trench shields, supporting walls, and slope boxes to help stabilize the messed up walls. You can alter the risky system for your needs by choosing:

- Shoring: A framework made of wood or metal to support and secure the trench wall.

- Excavation Slope: Trench walls are cut at an angle in order to prevent cave-ins.

- Trench Boxes (Protection): Metal boxes meant to be placed within trenches which would protect employees during a wall collapse.

ii) Daily Inspections Before Trench Entry: The Trench should always be inspected beforehand by a competent person to identify potential hazards. Make sure you check for:

- Air quality issues

- Collapse Indicators

- Signs of Water/Buildup

- Heavy machinery nearby

- Crack or even collapse signs

iii) Locate Utility Lines First: Before you dig mark power, gas, and water lines do not get damaged. Damaging gas lines come with the risk of major explosions while dismantling power lines will result in immediate electrocution.

iv) Keep Heavy Equipment Away from the Edge: Heavy machinery including trucks and backhoes positioned too close to the trench sides may compromise the structural integrity of the walls, resulting in uncontrolled cave-ins. You need to put equipment within a safe distance from the trench sides.

v) Safety Against Trenches For Workers: Conduct safety training regularly so people remain informed about potential dangers and protective measures. You must set a training cycle so everybody remains prepared and informed, which includes drills and information seminars.

4) Applications of Trenching

Utility Installation: Trenching is also a way of installing utility lines for water intake, sewage, and electric wires. These lines are concealed to protect them from damage and tampering.

Drainage Systems: In civil engineering, one of the functions of trenching is establishing drainage or sewage lines which ensure effective water flow management. During rainfall, there is the possibility of flooding your yard or even the roads, therefore water needs to be channelled into a drainage facility. Trenching assists in creating contours for drainage tubes that eliminate water from buildings and roads.

Foundation Work: Before erecting a structure, a firm base must be put in place. The effect is obtained by elongating a trench in the ground whereby concrete or other appropriate materials will rest. It ensures that the foundation is uniform and thorough for both domestic buildings, educational institutions, and high-rise buildings.

6) FAQs

i) What is trenching?

Trenching is the practice of digging a borehole in the earth that is long and deep. It is often done to put in utilities or to construct a drainage system to control the flow of water.

ii) What is the definition of trenching?

Trenching refers to the digging of a long, narrow hole in the soil, usually for the installation of utility lines, and drainage systems, or for putting in the foundations of a building.

iii) What equipment is used for trenching?

Trench digging is done by machines such as backhoe loaders, excavators, and specialized trenchers which move earth and are built to efficiently dig narrow trenches with precision.

iv) What are the safety considerations for trenching?

The safety part targets adherence to set measures, recognizing dangers, and deploying protective barriers such as trench boxes and shoring to avoid accidents and cave-ins.

v) When is a backhoe loader used in trenching?

A backhoe loader is used in trenching to scoop up and relocate materials, which is perfect for excavation and trenching work.

Conclusion

In a nutshell, in construction and digging, trenching is an important activity where deep and narrow holes are created to place crucial objects like water pipes, gas lines, and electrical cables. It is also used to perform foundational work and construct drainage systems. But as always, do not forget—Safety first. Accidents such as cave-ins can be avoided with the use of proper equipment and the right.

How to Find Excellent Trenching Equipment

Looking for reliable machinery for your trenching tasks? Well! Everstar’s high-quality backhoe loaders can be relied upon. What are you waiting for? Reach out to Everstar today and get expert guidance along with the best tools for your upcoming task!