Have you ever tried figuring out how you can safely and efficiently access the heights of a job site?

Well! Scissor lifts will do the job. They raise personnel and equipment to the desired height a lot faster and easier than doing it manually.

Scissor lifts are a requirement in any workplace because they allow for improved safety and increased productivity. Are you curious about which scissor lifts best cover your needs? Okay! Then read on!

1. What Is a Scissor Lift?

A Scissor lift is a device meant for workplaces that helps lift you and working equipment to high levels. The device works through a series of two or more platforms which are lowered or raised in a crisscrossing manner. They are used in construction places, warehouses, or during maintenance work.

Moreover, scissors lifts enable you to work efficiently and comfortably. Whether you need compact lifts for congested areas or high-capacity models for heavy lifting, scissors lifts with innovative features have it all!

2.How a Scissor Lift Works?

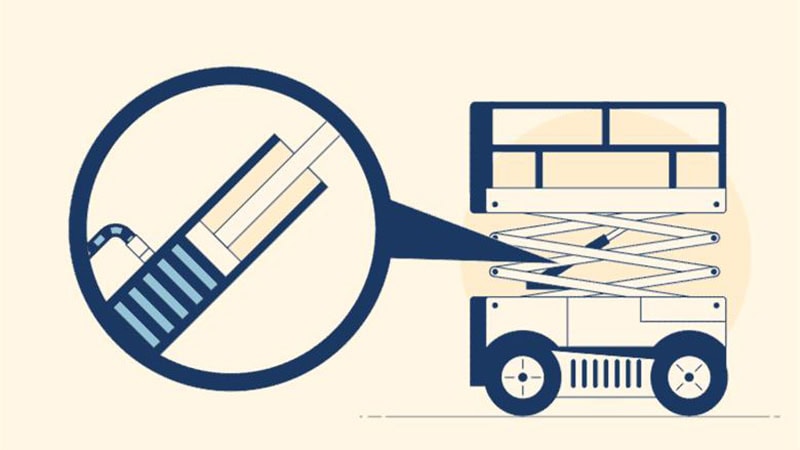

A scissor lift has an expanding and contracting crisscross mechanism that helps you reach working heights safely. Here’s how you use it:

Step#1) Powering the Lift

- To start you will need to switch on the power. An electric scissor lift uses a battery, making it ideal when working indoors. For outdoor job sites, fuel will be required for rough terrain scissor lifts.

Step#2) Activating the Hydraulic System

- The system will engage when you press the control button or the joystick is moved. Them, fluid is pushed into the cylinders by the hydraulic pump, creating pressure. With pressure created, the scissor arms will expand helping you move atop.

Step#3) Lifting the Platform

- You will be lifted smoothly as more fluid is pumped through the cylinders, ensuring uninterrupted commotion. With the controls, you can stop at your desired height.

- To assist you even more, some lifts offer the option for an extendable deck to help you reach additional heights without the hassle of moving the lift.

Step#4) Working Safely at Height

- At your desired height, you adjust the locking mechanism on the platform for additional support. You can now proceed with your tasks in a safe and effective manner.

Step#5) Lowering the Lift

- As a final step, press the lowering button. The hydraulic fluid is released and the scissor arms retract. The platform gradually delivers you to the ground.

3. Uses of Scissor Lifts

Scissor lifts enable comfortable and efficient lifting to different heights. Let’s examine their usage in real-life contexts!

3.1 Construction and Maintenance:

People in the construction industry understand the significance of working on towering spaces when being cautious and safe. Scissor lifts make it possible to install ceiling tiles, carry out electrical work like wiring, paint walls, or even fix HVAC systems. Unlike rickety ladders, these lifts provide a wide, stable platform to work on.

Case Study: A New York construction crew installed lighting fixtures in a commercial building using a 19-foot electric scissor lift. As the lift is compact and emits no emissions, it allows construction workers to work indoors without any floor damage.

3.2 Warehousing and Inventory Control:

A scissor lift also allows you to access unmanned towering shelves and spacious inventory in warehouses. Thus, it helps in reducing physical burdens and increases the efficiency or accuracy of inventory audits.

Case Study: The California warehouse managed its inventory using scissors and electric lifts instead of ladders, which saved 40% of its time. As a result, employees were able to restock and fetch heavy items with ease thus enhancing their productivity further.

3.3 Event Setup and Maintenance:

Setting up lighting, banners and the required decorations on high installations is a necessity in concerts, exhibitions, or corporate events. Scissor lifts assist in accomplishing these tasks safely and at a faster pace.

Real Example: For one of the music festivals, a London Stadium used rough terrain scissors lifts to set up LED screens and stage lights. With high capacity and all-terrain tires, the lifts had no problems transporting heavy equipment (up to 1,500 lbs).

3.4 Small Scissor Lifts for Tight Spaces:

Sometimes, the job requires accomplishing tasks in small rooms, blended job sites, narrow aisles, and contested spaces. Small electric scissor lifts are best suited for such environments as they are optimized for indoor use.

Customer Review: “We utilize a 13-foot scissor lift in our warehouse and it’s been great! It is compact, which means it fits through standard doors and makes restocking so much easier.” – Warehouse Manager Texas

In short, if your goal is to increase safety and productivity at work, investing in a scissor lift will address those needs, and we recommend you explore Everstar scissor lift options.

4. Types of Scissor Lifts

When selecting a scissor lift, it must match the specific requirements of the job you intend to do. No matter if your work is indoors, outdoors, on challenging surfaces, or in constricted areas, there is a suitable option available. Let us go through the best options that allow you to do your work efficiently and safely.

4.1 Electric Scissor Lifts: Suitable for Indoor Use

An electric scissor lift is perfect for indoor tasks as it does the job very well. These lifts operate on electric batteries meaning there is no noise or smell to contend with. They are ideal for warehouses, shopping malls, and general office maintenance.

Why You Should Choose It:

- Zero emissions – Safe for work indoors

- Quiet working – Lessens noise pollution

- Operable with a single charge – Up to 8 hours

- Space-saving – Goes through normal doors and elevator

Best for:

- Changing overhead lighting, servicing HVAC units, and placing items on tall cabinets.

Customer Review: “Our team uses electric scissor lifts on a daily basis for warehouse stocktaking. They are exceptionally quiet, easy to pilot, and they do not interfere with business operations.” – Logistics Manager, New York

4.2 Diesel Scissor Lifts: Best for Outdoor Projects

If your work is outdoors, then a diesel scissor lift would serve you best. These lifts come with powerful engines, greater weight limits, and quicker lift speeds. They’re perfect for use at building sites and during bridge repairs or any major upkeep task.

Why You Should Choose It:

- Heavy-duty lifting – Supports up to 2,500 lbs

- Higher platform heights – Reaches 30 to 60 feet

- Long working hours – Runs all day on a single charge

- Rough terrain capabilities – Handles uneven surfaces and slopes

Best for:

- Building construction, large maintenance projects, and bridge repairs

Case Study: A construction company in California used a diesel scissor lift to install steel beams on a high-rise. The lift’s stability and height reach allowed the team to finish 30% faster than expected.

4.3 Rough Terrain Scissor Lifts – Best for Challenging Environments

If you need to work in tough conditions, a rough terrain scissor lift will help you stay safe and productive. These lifts come with four-wheel drive, oversized tires, and self-leveling technology to help you navigate rough surfaces.

Why You Should Choose It:

- It has more weight – Added capacity for tools and personnel.

- Self-leveling system – Works on sloping and bad surfaces.

- High wind resistance – Retains stability under strong outdoor conditions.

- Heavy duty tires for all-terrain – Able to traverse through mud, gravel, and rocky passages.

Best for:

- Construction zones, stadium maintenance, and wind turbine servicing.

4.4 Mini or Small Scissor Lifts – Perfect for Restricted Areas

If your work includes minimal spaces, a mini scissor lift is just for you. These lifts are compact, light, and easy to lift and reposition making them ideal to use in narrow paths, congested rooms, and even on sensitive flooring.

Why You Should Choose It:

- Shorter platform heights – Extends up to 19 feet.

- Battery-powered – No emissions, suitable for indoor places.

- Extremely lightweight design – Easy to transport and operate.

- Fits in narrow spaces – Ideal for small warehouses and hospitals.

Best for:

- Hospitals, libraries, retail stores, and setting up events indoors.

Case Study: The mini scissor lift was used to install a light in a Chicago museum without further damaging the floors. The lift is small and lightweight, making the job easy and risk-free.

5. How to select the Best Scissor Lift for Your Needs?

Before you set out to purchase a scissor lift, there must be some forethought put into scoping the project. Here’s how:

- Think about your project site: Will it be an enclosure? Is there a need to turn into some claustrophobic area?

- Analyze the lift: Look at weight volume, platform height and limit, along with the power type.

- Brand and model comparison: Check leading manufacturers’ lists and startup cases. You can go for Everstar Machinery, which is the china’s leading construction equipment manufacturer having 15 years of experience in the production line.

- Verging on talking to someone: Scan a scissor lift specialist’s eyes to understand the best solution. Also make sure that it meets the safety standards.

Selecting the correct scissor lift can enhance efficiency, increase safety, and complete tasks in a quicker manner.

6. Benefits of Using Scissor Lifts

- Enhanced Safety: As mentioned before scissor lifts have guardrails, non-slip platforms, and sturdy bases that prevent falls. They are made to keep your safety first while working at elevated levels. No matter the condition of your working sights, scissor lifts do not need much time for setup. Once set up, scissor lifts remain steady allowing you to focus on your job. Unlike scaffolding, A scissor lift is instantaneously functional.

- Enhanced Productivity: If you are looking to reach certain heights within the least amount of time, look no further than a scissor lift. When looking to go up and down a lift, all it takes is the push of a button. This ease of access saves time and energy allowing maintenance and repairs and even installations to be carried out in a much easier way.

- Versatile Applications: A scissor lift is guaranteed to fit your working requirements whether it be for construction, warehouses, retail stores, events, or even hospitals. Scissor lifts enable you to operate with ease and safety, be it when fixing lights, stacking inventory or even fix signs.

FAQs

What is a scissor lift?

A scissor lift is an aerial work platform which has a crisscross lifting mechanism used to elevate the working platform to accessible heights.

What are the different types of scissor lifts?

The basic varieties of scissor lifts are electric, diesel, rough terrain, and mini or small lifts. Each of these categories serves useful purposes in different locations.

What are scissor lifts used for?

Scissor lifts are used in construction, maintenance, warehousing, events, and more to safely reach elevated spaces.

Can I use a small scissor lift indoors?

Yes, especially electric small scissor lift models are best suited for indoor use as they are low-emission compact machines.

How do I choose the right scissor lift for my needs?

When selecting a scissor lift, consider the maximum height, whether you will use the lift inside or outside, and how much weight you plan on lifting.

Conclusion

Ultimately, scissor lifts are incredibly important for reaching high locations in a safe manner.

They are electric, diesel, rough terrain, and mini lifts, each of which is customized for different tasks and settings. Scissor lifts also provide safety by supplying a stable platform, which improves efficiency because tasks are able to be completed at greater heights.

To operate safely, always follow the instructions provided by the manufacturer, make sure there is adequate training for the operators, inspect and maintain the lift regularly, and use the required personal protective equipment.

Everstar is trusted for offering custom solutions, so reach out today to find the perfect scissor lift for your project!