Key Takeaways

- Electric boom lifts offer sustainable, zero emissions performance for indoor, and outdoor work environments.

- Electric articulating boom lifts provide precise positioning and flexibility in tight spaces.

- Quiet functionality and low noise levels enhance comfort and allow night shifts.

- Minimal maintenance and no fuel needs reduce operating costs.

- Advanced safety systems and reliable battery technologies improve productivity and uptime.

These machines have become a performance powerhouse in modern elevation solutions, replacing combustion engines with clean, efficient energy while offering impressive height capabilities for elevated tasks.

As construction sites demand eco-friendly equipment, these machines deliver sustainable results without compromising height. You can choose between telescopic and articulating boom lifts for indoor and outdoor use due to zero emissions, quiet handling, and a wide range of models for different needs.

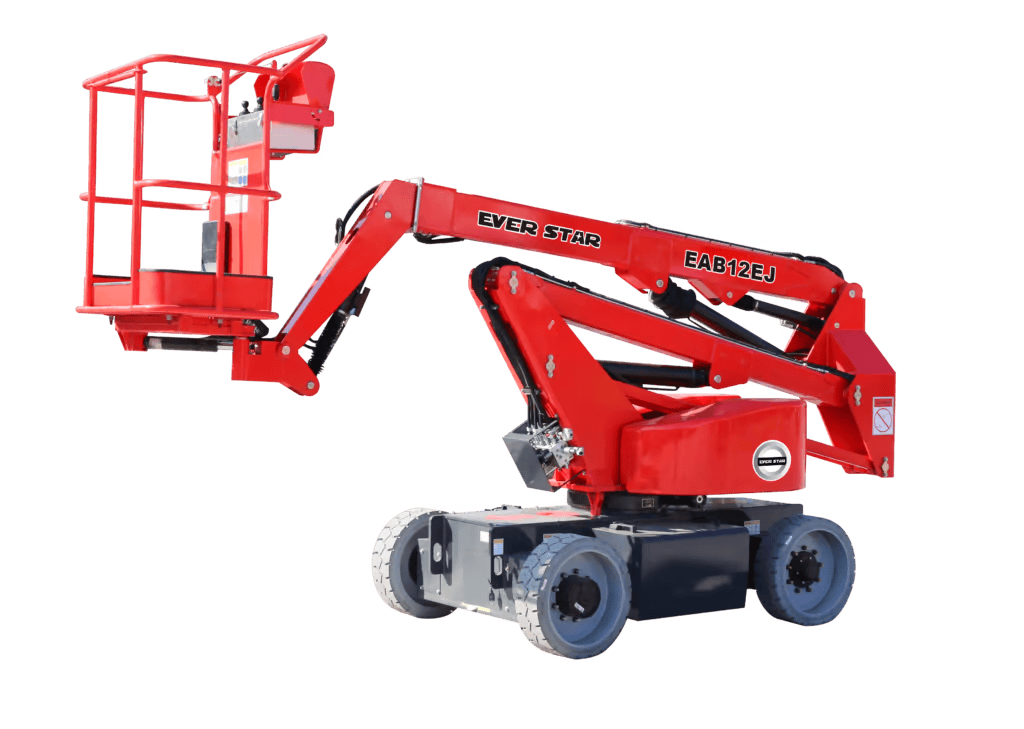

Everstar boom lifts are designed to provide efficient, quiet, and emission-free function, making them ideal for indoor and sensitive environments.

Understanding Zero-Emission Boom Lifts

A zero-emission boom lift operates on rechargeable batteries, eliminating the tailpipe emissions of diesel engines. These machines are designed for smooth operational capability, enabling quiet work indoors while maintaining high results outdoors.

Compared to diesel alternatives, electric articulating boom lifts produce zero emissions and lower vibration, making them the ideal option for indoor applications or environmentally sensitive job sites.

Types of Zero-Emission Boom Lifts

These machines are assembled of a platform or bucket connected to a hydraulic arm on a mobile base, making them ideal for maneuvering in narrow aisles.

Electric Articulating Boom Lifts

An electric articulating boom lift uses multiple pivot joints, giving operators the ability to move around obstacles and access areas previously inaccessible.

This compact design enables precise positioning and easy maneuvering in limited spaces, such as narrow aisles, warehouses, or repair zones.

These electric articulating boom lifts typically reach between 40 ft and 80 ft, offering a range of height options and impressive horizontal outreach while staying quiet and efficient during every work cycle.

Electric Telescopic Boom Lifts

The telescopic option offers straight-line reach and higher height, often up to 130 ft, making it suitable for outdoor projects where vertical access is essential.

When exploring the best boom machine for your project, telescopic models provide reliable results on structured job sites, extended outreach, and stable platforms, especially where lasting and power are required.

Environmental and Noise Benefits

Zero emissions make these machines vital for indoor environments or low-emission zones, like hospitals or event centers.

On the jobsite, electric boom lifts offer significant advantages due to their low noise and zero emissions, making them suitable for a wide range of jobsite conditions, including urban areas and sensitive environments.

Their quiet handling allows finishing work in occupied buildings or job sites where silent operation is required. Beyond compliance, they contribute to environmental standards recognized by institutions such as the Global Reporting Initiative (GRI), helping companies align with sustainability goals.

The absence of fuel fumes improves air quality in job sites, making it safer for personnel and nearby staff during various tasks.

Operational Advantages

Because electric articulating boom lifts generate almost no noise or vibration, they’re ideal for night or noise-sensitive work. Their non-marking tires allow work indoors without damaging floors, while precise positioning systems support smooth, accurate movement.

The compact design of the boom machine ensures easy navigation in tight spaces, maximizing productivity even in limited areas. This makes the electric articulating boom lift a superior solution for complex indoor projects where an articulating boom lift is required.

Maintenance and Cost Efficiency

Upkeep for these machines is minimal compared to combustion alternatives. No oil changes or exhaust systems mean fewer breakdowns and lower downtime.

The result is reduced costs and higher productivity across multiple jobsites. Over time, companies meet their requirements while saving on fuel and service intervals, making electric articulating boom lifts a cost-effective investment.

Safety and Technological Features

These machines come equipped with advanced systems, including automatic stabilization, anti-rollback brakes, and overload sensors. Smooth controls and proportional driving assist ensure secure handling, even in elevated areas.

Modern battery technologies, such as lithium-ion, extend runtime and enhance dependable results throughout each job. These capabilities make electric articulating boom lifts a good balance of technology and security, helping workers handle complex projects with confidence.

Use Cases and Industry Applications

Electric articulating boom lifts are ideal for a wide range of applications, from warehouses and factories to public venues. An articulating boom lift is often the only solution for reaching difficult areas and navigating around obstacles in these environments.

These lifts offer exceptional versatility. Their ability to work quietly and cleanly makes them ideal for installation, painting, and finishing work inside buildings. On outdoor projects, these machines offer smooth driving and hybrid adaptability for mixed-use sites.

Many manufacturers offer different models with various capabilities, ensuring durability and performance across different project requirements. Event setups, hospitals, and urban construction all benefit from their precision and low impact on the surrounding environment. These machines are designed to meet sustainability demands while improving efficiency in modern work environments.

FAQs – Boom Lifts

What are the main differences between electric and diesel boom lifts?

The key difference lies in the energy source, height capability, and zero emissions production. These machines run quietly and require less maintenance, making them perfect for indoor or urban sites. Diesel variants, while more powerful, create exhaust gases and noise, making them better suited for outdoor heavy-duty tasks.

Can boom lifts be used outdoors?

Yes, they can operate outdoors efficiently. Most variants are designed with weather-resistant enclosures and robust tires, enabling reliable operation on paved or semi-rough field locations. Some hybrid variants even combine battery and engine power for extended runtime.

How long does an electric boom lift battery last?

Battery duration depends on the model and use, with several factors affecting performance. On average, an electric articulating boom lift runs 8–10 hours per charge. Proper maintenance and efficient operation extend lifespan, while fast-charging features and lithium-ion options improve runtime and overall productivity on jobs.

What safety features are standard on boom lifts?

Most boom lifts include built-in safety systems such as tilt alarms, automatic stabilization, overload sensors, and proportional controls that enhance precision at height. These features support compliance with OSHA and international protection standards, protecting both operators and surrounding personnel during elevated operations.

Are small electric platform lifts safe for indoor use?

Yes, small electric aerial platforms are specifically designed for indoor environments. Their compact structure, zero emissions, and quiet operation make them ideal for maintenance, installation, and finishing work in confined spaces. They provide safe elevation with smooth handling while protecting air quality and minimizing disruptions in sensitive facilities.

Conclusion: Why Electric Articulating Boom Lifts Are the Future of Elevated Work

Zero-emission machines redefine efficiency and sustainability. They offer quiet handling, minimal upkeep, and dependable results while helping companies meet environmental requirements.

With articulating and telescopic alternatives available, including the highly versatile articulating boom lift, these solutions remain the ideal choice for both indoor and outdoor applications. The electric articulating boom lift, in particular, is driving the transition toward cleaner, smarter job sites.

Contact Everstar Machinery for Expert Advice

Looking to choose the right electric articulating boom lift for your project? Contact the Everstar Machinery team for guidance and tailored solutions.

Our experts will assist your team in finding the ideal machine to satisfy your needs, whether for industrial facilities, indoor upgrades, or eco-friendly outdoor operations.

Visit Everstar Machinery and explore the complete portfolio designed to improve productivity and long-term results.