Key takeaways

- Multifunctional accessories, such as auger drills, DTH hammers, and ground screws, allow a single pile driver to handle a variety of projects, providing a versatile solution for different ground conditions in today’s industrial world.

- Regular maintenance and quick-change systems protect steel components and reduce downtime, keeping equipment reliable for long hours and supporting heavy loads with consistent weight distribution.

- Everstar offers training, engineering guidance, and services to help operators meet industry demands and be ready to manage different pile types effectively.

- Pile driver projects, from screw piles to solid foundations, vary depending on site requirements, giving installers the flexibility to work efficiently across multiple environments and set up projects quickly.

In today’s construction market, multifunctional accessories are key to maximizing efficiency and cost control. Auger drills, DTH hammers, ground screws, and other attachments allow a single pile driver to tackle diverse tasks — from solar installations to guardrail posts.

Everstar leads this approach by designing adaptable pile driver accessories that perform reliably across varied ground conditions.

These tools simplify maintenance, minimize downtime, and optimize performance, providing you with a versatile solution for modern projects.

The Power of Multifunctional Pile Drivers

Modern structures demand tools that do more with less — less time, less maintenance, and less idle equipment. A multifunctional pile driver delivers exactly that. With the right accessories, one machine can handle diverse tasks across multiple projects, helping teams reduce costs and stay on schedule.

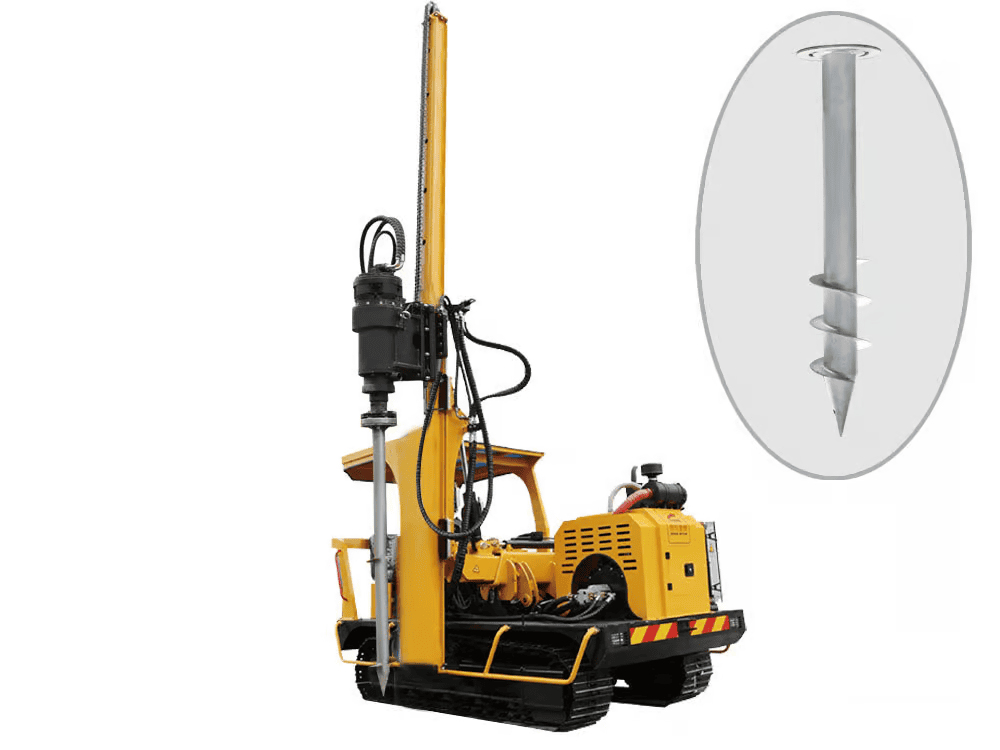

Key accessories make this possible: auger drills provide fast, precise drilling in various grounds; DTH hammers efficiently penetrate rock and concrete; and ground screws allow quick, eco-friendly foundation installations.

Everstar’s pile driver systems are engineered around this principle, combining strength, precision, and adaptability, with attaching accessories that are simple and straightforward for digging.

Adapting to Different Ground Conditions

Ground conditions can change dramatically from one job to another, making versatility essential. Everstar’s pile driver accessories are designed to withstand across different ground types — from sand and soft soil to clay and rock — without compromising accuracy, quality, or power.

- Ground screws offer a sustainable alternative to concrete or deep foundations, making them ideal for eco-sensitive projects, decks, and quick installations.

- Anchor bolts allow precise placement even in areas that are difficult to access, providing stability where traditional foundations can’t be used.

- Auger drills provide fast, accurate digging in construction, agriculture, and landscaping. Their robust design allows drilling from 100mm to 500mm in diameter, efficiently handling soft, frozen, and compact soils alike.

Solid Foundations – When and Why They Matter

While multifunctional pile drivers excel at small- and medium-scale installations, knowing when to use solid foundations guarantees safety, stability, and reliable performance. The right accessory allows Everstar equipment to be installed efficiently, even in challenging ground conditions.

Building Projects vs. Small-Scale Jobs

Everstar’s portable pile driver systems excel at installing solar panels, fence posts, signage, and small foundations. While the systems are versatile, large-scale building projects generally require heavy-duty, vehicle-mounted equipment, which falls outside Everstar’s main services for this industry.

This distinction highlights the limits of handheld and multifunctional pile drivers while showing their efficiency, advantages, and precision for small-scale and specialized projects, assuring customers can match the right tool to each foundation type of work.

Key Accessories for Everstar Pile Drivers

Everstar offers a range of accessories designed to expand the capabilities of its pile driver systems. Each accessory supports specific project scenarios, including solar farms, fencing, and foundation work, ensuring reliable results in every application.

- Hydraulic Hammers: High-performance and precise, Everstar’s hydraulic hammers deliver up to 1960 Joules of impact power, ideal for solar installations, fencing, and light construction projects. Their efficient energy transfer makes them suitable for remote or environmentally sensitive sites where consistent performance is crucial.

- Auger Drills:Engineered for speed and accuracy, these augers handle various ground conditions with ease — from soft loam to frozen clay. They can drill complete holes ranging from 100mm to 500mm, providing a clean and stable base for posts or foundations while reducing drilling time and operator effort.

- DTH Hammers: Designed for high-impact drilling in rock and concrete, Everstar’s Down-the-Hole (DTH) hammers achieve up to 30% faster penetration than conventional systems in this environment. Their durable design and efficient energy transfer result in lower fuel consumption, reduced downtime, and extended tool life.

Installing Ground Screws & Screw Pile Foundations

Accessories turn a pile driver into a complete foundation system. Ground screws, anchor bolts, and screw piles can be installed quickly for solar structures, signage, and light projects.

For example, installing a solar field with ground screws instead of concrete piles can cut setup time by more than half. Load-bearing capacity remains strong for appropriate applications, and soil disturbance is minimized.

Everstar’s systems handle these common pile driving challenges with consistent torque control and precise placement. Operators can maintain productivity while guaranteeing long-term stability for small-scale and specialty foundations.

Maintenance and Quick Change Systems

Pile driver maintenance preserves drilling accuracy and prolongs equipment life. Everstar’s quick-change system allows operators to swap accessories — augers, DTH hammers, or ground screw drivers — in minutes, reducing downtime and keeping projects on schedule.

Technicians can inspect components to detect wear or corrosion. Applying protective measures safeguards equipment, lowers the risk of failure, and maintains reliability in heavy-duty conditions, supporting consistent performance across every project.

Cost, Efficiency, and Environmental Impact

Investing in multifunctional pile driver tools improves ROI. A single unit with interchangeable accessories reduces the need for multiple machines, lowering capital and maintenance costs while improving labor efficiency across various projects.

Environmental advantages also play a key role. Ground screws eliminate the need for concrete foundations, reducing material waste and carbon emissions.

According to the EIA (Energy Information Administration), reducing energy-intensive materials helps lower a project’s overall environmental footprint. Everstar combines cost control, recommended sustainability procedures, and performance to deliver long-term value.

Customization and Support from Everstar

Selecting the right accessory depends on soil type, project depth, load requirements, and installation goals. Everstar provides engineering consultation, training programs, product customization, and customer support to ensure each pile driver system is used safely and with the correct tools.

By aligning the equipment solution with project needs, you can ensure peak performance and deliver consistent results from start to completion across solid foundation, agricultural, and landscaping projects.

FAQ – Pile Drivers

What is the hammer of a pile driver?

The hammer is the impact tool of the pile driver that delivers force to drive posts, piles, or anchors into the ground. Everstar’s hydraulic hammers provide up to 1960 Joules, ensuring consistent penetration across various soil types and project requirements.

What are the disadvantages of ground screws?

Ground screws are fast and eco-friendly but have some limitations. They may not support extremely heavy loads, require precise torque control for stability, and can be less effective in highly rocky soil compared to traditional concrete foundations.

What is screw pile foundation?

A screw pile foundation consists of steel screw piles driven into the ground to support structures. It offers fast installation, minimal soil disturbance, and reliable load-bearing capacity, making it suitable for solar farms, fencing, signage, and small to medium projects.

Can Everstar Pile Drivers Install foundation anchor bolts?

Yes. Everstar’s multifunctional pile drivers, with the correct accessory, can install foundation anchor bolts efficiently. They provide consistent torque and alignment, even in tight or challenging locations, making them suitable for signage, light structures, and specialized foundation projects.

How quickly can accessories be changed on Everstar machines?

Everstar machines feature a quick-change system that allows operators to swap accessories in minutes. Augers, DTH hammers, or ground screw drivers can be replaced easily, reducing downtime and maintaining consistent workflow on foundation, agricultural, and landscaping projects.

Conclusion: Maximizing Foundation Versatility with Everstar Accessories

Using a single pile driver with multiple accessories maximizes flexibility, productivity, and cost savings across complex jobs, from solar installations to guardrail posts. Augers, DTH hammers, and ground screws each handle specific tasks efficiently.

Augers provide fast, precise drilling; DTH hammers penetrate rock and concrete; ground screws enable quick, eco-friendly foundation installations. Together, they let one machine manage diverse projects with ease, reducing downtime and simplifying operations.

Choosing the right tools requires guidance and quality. Everstar’s support and engineering expertise minimize the hassle of planning and execution while delivering optimal performance on every project, no matter the scale or ground conditions.

Consult Everstar Experts for Your Next Project

Contact Everstar Machinery’s experts to discover your accessory needs and find the right solutions for your project.

Our team can provide you with detailed guidance to guarantee each system is matched correctly, making it easy to plan and execute your tasks. Request a catalog to discover the full range of tools, attachments, and solutions available.