Key Takeaways

- Understanding how to read a boom lift load chart ensures stable and controlled lifting by clearly showing maximum load, boom angle, horizontal outreach, and platform limits.

- Selecting the correct Everstar Boom Lift type—articulating boom or telescopic, diesel or electric—matches equipment to project requirements.

- Daily checks of load, accessories, outriggers, and job site conditions prevent overloads and maintain stability limits.

- Following EN 280, ANSI, OSHA, and Everstar guidance reduces risks and ensures compliance on every lift.

On any construction site, safety begins with selecting equipment that meets the job’s specific demands. A boom lift provides access to elevated or hard-to-reach areas, making it essential for tasks such as building maintenance, tree trimming, electrical work, and other maintenance projects.

A load chart shows the maximum weight the lift can safely carry at different boom angles, outreach values, and platform positions. Following it prevents overload, instability, structural failure, accidents, and costly equipment damage.

This article explains how to read an Everstar Boom Lift load chart, covering layout, key metrics, field application, manufacturer guidance, and safety practices that ensure predictable and efficient lifting operations.

Understanding Boom Lift Load Chart Structure

A boom lift load chart maps how the lift behaves as the boom rises, rotates, or extends. It allows operators to avoid unstable positions and plan work that stays within safe operating limits.

The structure shows how capacity changes with boom length, boom angle, and operating radius. These variations guide everyday tasks such as facade maintenance, overhead installation, or steel assembly.

Everstar offers telescopic and articulating boom lifts in both diesel (230–480 kg) and electric (200–480 kg) models, allowing operators to match the lift type, reach, and load capacity to the demands of each project.

Chart Layout Explained

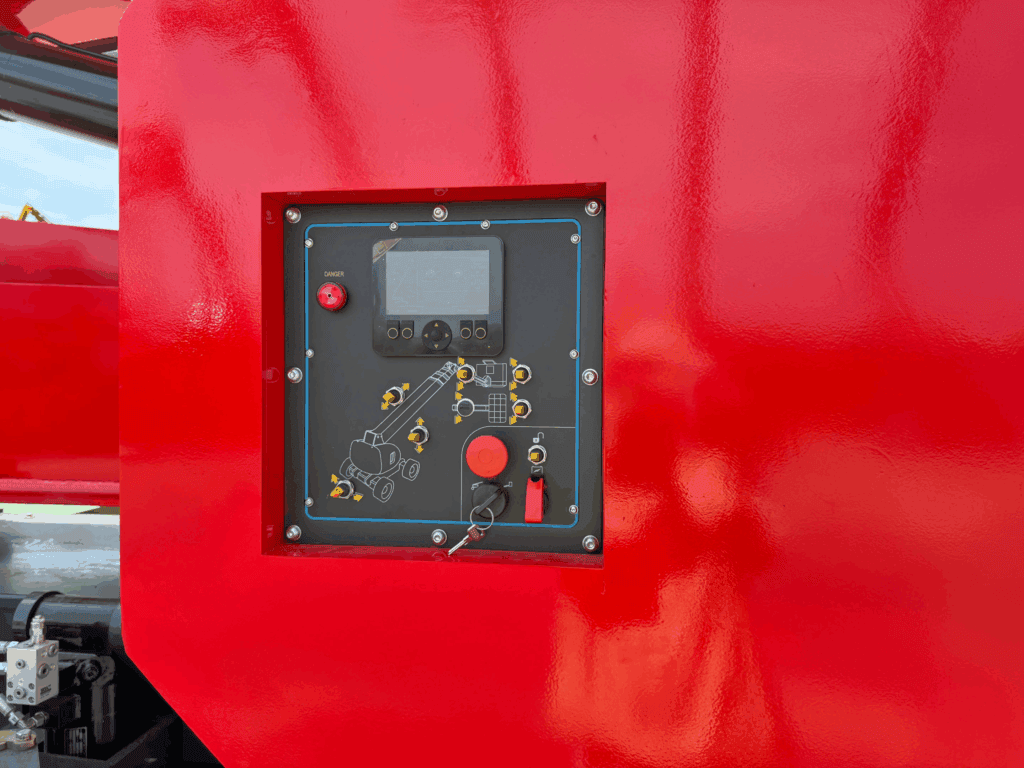

Standard load charts include maximum load capacity, boom length, range diagram, boom angle, counterweight information, and operating restrictions. Each section helps the operator understand how the boom lift equipment responds in different configurations.

For example, a lift may handle 230 kg at a moderate horizontal outreach, while the permitted load decreases as the boom extends further. The chart’s left column and bold line indicate these maximums before a worker enters the platform or the arm begins moving.

Decoding Symbols and Key Terms

Symbols indicate no-go zones, wind limits, platform orientation, bucket capacities, and outrigger positions. For example, a red zone shows that the boom cannot extend safely at a given angle with maximum load. Following these prevents tip-overs or overloads.

Reduced-capacity work areas indicate the limits when accessories or tools are added, increasing the platform’s weight. Operators must adjust load or outreach accordingly. These zones appear in Everstar charts to prevent misjudgment and maintain stability limits on uneven ground.

Operational boundaries define the maximum boom extension, rotation, and angle for a safe job. Misinterpreting these can lead to instability, contact with obstacles, or stress on outriggers. Everstar charts clearly mark these limits for quick field reference and comparison with the crane load chart.

Interpreting Critical Metrics

Each metric on a boom lift load chart helps determine the stability and safe operation of the equipment. Boom length, outreach radius, platform angle, and load capacity determine the safe reach and height of the lift. Understanding these numbers ensures operators plan lifts that align with site conditions and equipment limits.

Maximum Load and Outreach

Charts specify the maximum permitted load at each boom angle and outreach. For example, a 10-meter radius may allow 300 kg, but extending it to 14 meters reduces the capacity to 220 kg. Operators must verify these values for every configuration, including platform extensions and added tools, to prevent overload and damage to equipment.

Using Load Capacity Tables

Capacity tables or graphs indicate changes when the boom extends, the platform carries multiple workers, or accessories are added. If a toolkit adds 50 kg, locate the adjusted row or column to confirm the lift remains within safe limits. This step ensures proper planning and prevents tipping or structural stress.

Integrating Crane Load Charts and Boom Trucks

While this guide focuses on the boom lift load chart, operators often coordinate with cranes or boom trucks, making understanding a crane load chart vital. Each chart indicates the crane’s lifting capacity, operating radius, and safe boom angles.

A crane operator must review the motion chart before starting work to ensure loads remain within rated limits. This awareness supports crane safety, improves coordination with boom lift operations, and confirms the team’s ability to handle materials efficiently without exceeding stability limits.

Field Application and Safety Practices

Daily use of a unique load chart requires operators to select the correct chart for the Everstar machine’s current configuration. By checking boom length, angle, and load radius against the expected weight, users can confirm the lift operates within safe limits and prevent accidents.

Operator Checklist for Load Charts

Before using a boom lift, operators should follow a structured checklist to ensure safe lifting and avoid overloads. Each step helps align the planned lift with the machine’s rated capacity and environmental conditions.

- Verify boom type and extension: Confirm whether the lift is articulating or telescopic, and whether it is an electric or diesel boom lift. Check the boom length against the load chart.

- Check platform size and accessories, including tool kits, extension platforms, and worker safety equipment. Adjust the allowed load in the chart to prevent exceeding limits.

- Confirm load against chart limits: Match the combined weight of personnel, unit, and materials to the permitted capacity at the given radius.

- Review counterweight and outriggers: Ensure counterweights are correctly positioned and outriggers are fully deployed to maintain stability during lifting operations.

- Assess environmental conditions: Check wind speed, slope, ground firmness, and nearby obstacles. Unsafe conditions can significantly reduce load capacity or create tipping hazards.

Mistakes to Avoid

Common errors include ignoring wind speed, miscalculating total load, or using the wrong boom angle. Everstar support provides guidance, calibration tools, and operator training to ensure every setup is safe and the lift is adequately equipped for the task, maintaining structural strength throughout operations.

Operators should also follow OSHA guidelines for aerial lift safety, including proper load handling, platform positioning, and fall protection, to prevent tip-overs, falls, and electrical hazards when the vehicle is in use.

Compliance, Regulatory, and Manufacturer Guidance

Safe boom lift operation relies on following regulations and manufacturer guidance. Everstar ensures that operators interpret load charts correctly, understand machine limitations, and apply safety measures that comply with EN 280 and ANSI standards.

Regulatory Standards and Everstar Guidelines

EN 280 and ANSI define maximum load, boom stability, and operational limits. Everstar provides certified load charts, retraining programs, and scheduled inspections to maintain accurate measurements, proper boom lift maintenance, prevent misuse, and guarantee compliance with local and international requirements.

FAQ: Aerial Lift Chart

What information does a boom lift load chart provide?

A chart details maximum load, boom length, boom angle, outreach, counterweight, and platform limitations. It includes symbols for no-go zones, wind restrictions, and outrigger guidance. Operators across industries use this vital information to plan safe lifts and prevent overload.

How can I tell if I’m exceeding a boom lift’s capacity?

Exceeding a boom lift’s capacity occurs when the platform load, including personnel, tools, or accessories, surpasses the chart’s maximum at a given boom angle or outreach. Operators must cross-reference the weight with the correct load radius and boom configuration to ensure operation remains within safe parameters.

What are the risks of ignoring load chart guidance?

Ignoring load chart guidance can result in tip-overs, platform collapse, or structural damage to the lift. It increases the risk of worker injury, equipment failure, and regulatory violations. Correctly interpreting charts, adhering to limits, and consulting Everstar guidance help reduce hazards and maintain operational efficiency.

Conclusion: Ensuring Safety Through Chart Mastery

Mastering boom lift load charts is crucial for ensuring daily safety, maintaining regulatory compliance, and optimizing operational efficiency. Proper interpretation of load capacity, boom angle, and outreach ensures operators avoid overloads, tip-overs, and unsafe configurations while keeping projects on schedule.

Using Everstar load charts, while considering environmental conditions and machine limitations, ensures that teams choose the appropriate type—articulating or telescopic, diesel or electric boom—for each task. This maximizes performance, safeguards workers, and ensures reliable results across projects.

Connect with Everstar Experts

Contact Everstar Machinery specialists for personalized load chart guidance, onsite operator training, or full access to the lift equipment documentation. Ensure that every lift is planned, executed safely, and aligned with both regulatory standards and the machine’s capabilities.