Key Takeaways

- Aerial lifts allow workers to perform elevated jobs safely and efficiently, supporting complex construction and maintenance work.

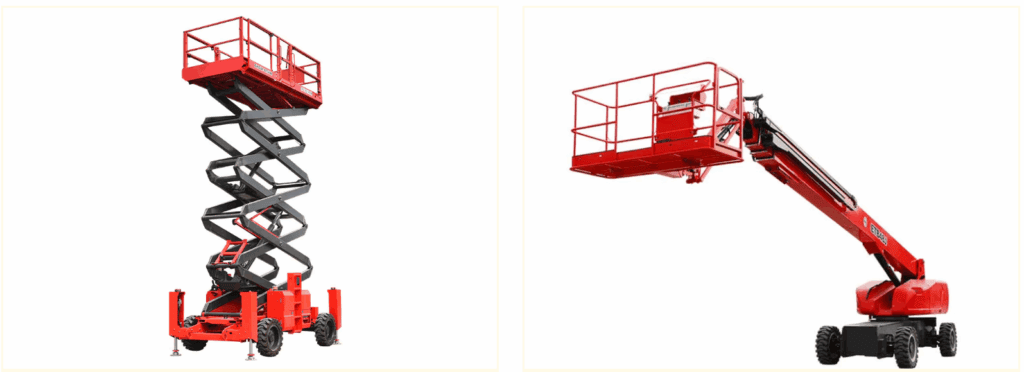

- Scissor lifts move vertically and handle heavier loads on flat ground.

- Boom lifts reach higher and move both vertically and horizontally to access hard to reach places.

- The right aerial lift depends on height, terrain, and reach needs.

- Regular maintenance and proper operator training ensure long-term safety and reliability.

Aerial lifts safely elevate workers and tools to high areas, lowering risks compared to ladders or scaffolding.

Two of the main types of lift equipment for utility work are scissor lifts and boom lifts. Scissor lifts move vertically with high stability, while boom lifts offer extended reach and flexibility.

Selecting the right aerial lift is important because design, reach, and safety all affect performance and worker safety on the job site. You can walk through an essential guide to understand the essential factors to consider before

Defining Scissor Lifts and Their Core Characteristics

A scissor lift is an aerial platform that raises straight up using a cross-pattern mechanism powered by hydraulics, pneumatics, or mechanical pressure.

The crisscross frame folds and extends vertically, creating a steady and controlled lift suitable for multiple workers and tools.

Typical Uses and Operational Strengths

Scissor lifts are commonly used in different types of utility tasks in construction sites, electrical work, and warehouses. Their wide platforms make them capable of supporting several weights.

Electric scissor lifts models are best indoors since they produce no emissions and use non-marking tires. Diesel or rough terrain scissor lifts perform well outdoors, managing uneven ground and heavier materials.

Different scissor lift models by Everstar reach up from 20 to 50 feet, offering strong load capacity for safer vertical work.

Understanding Boom Lifts and Their Versatility

A boom lift, also known as a cherry picker or man lift, features a hydraulic arm that can extend, bend, and rotate, enabling both vertical and horizontal reach. Everstar offers diesel and electric models of boom lifts, designed for specific applications where maneuverability, versatility, and maximum reach are essential.

Whether it is a telescopic or articulating equipment, this machine allows workers to drive to hard-to-reach places and move over obstacles that scissor lifts cannot access, completing tasks in challenging environments.

Use Cases Highlighting Reach and Flexibility

Boom lifts are used in construction, maintenance, and specialized outdoor work at challenging heights and angles.

Telescopic or straight types of boom lifts offer maximum height and forward reach for open job sites, while articulating boom lifts bend around corners for precision in tight spaces. Electric boom lifts are zero-emission and ideal for indoor or low-noise areas.

Although some models of boom lifts support less weight, this machine excels in reach, access, and control.

Key Differences Between Scissor and Boom Lifts

Scissor and boom lifts differ mainly in their movement direction, reach, and weight capacity. Here are some of the specific applications for these two types of machines:

Scissor lifts

- Move only vertically with strong stability on flat ground

- Offer larger platforms and higher load capacity for crews

- Are simpler to operate and maintain

Boom lifts

- Extend vertically and horizontally to access higher or hard-to-reach locations.

- Improve maneuverability around obstacles and confined spaces.

- Include telescopic and articulating models well-suited for rough terrain.

Safety and OSHA Regulations for the Job Site

Both scissor lifts and boom lifts fall under OSHA’s aerial lift standards. Workers must use guardrails, check controls, and inspect the platform before use.

Scissor lifts should never exceed their rated load capacity or maximum height. Boom lifts require extra attention to balance, wind, and ground stability.

Consistent training and regular care keep every lift safe and compliant.

Factors to Consider When Choosing an Aerial Lift

Choosing the right aerial lift depends on job site conditions, height, and terrain. Electric scissor lifts work best indoors or on flat floors. For uneven or outdoor conditions, diesel-powered rough terrain models provide traction and stability.

When obstacles or limited space are present, an articulating or telescopic boom is a better option. Projects that need multiple workers or heavy tools are ideal for scissor lifts, while jobs requiring longer reach are better suited for boom lifts.

Cost, Care, and Training Implications

Scissor Lift models offer superior cost-effectiveness and durability, featuring simpler mechanical systems that ensure lower overall upkeep requirements.

For projects demanding maximum reach, boom lifts may require a higher initial investment, which is justified by their complex hydraulic arms, superior maneuverability around obstacles, and industry-leading operational range.

Regular maintenance keeps both machine types reliable. Operators should inspect hydraulics, tires, and controls daily. On the other hand, training reduces downtime, expands machine lifespan, and enhances operational protection across different industries.

Innovations and Trends in Aerial Lift Technology

Modern aerial lift technology emphasizes efficiency and safety. Most new lifts are battery-powered, providing longer operation times and zero emissions. Electric and cable-operated lifts are common in warehouses, while diesel units are still the most suitable choice for off-road or rugged terrain.

Smart sensors, automatic leveling, and remote diagnostics help workers monitor stability and identify issues early. Manufacturers now use lighter materials to reduce fuel consumption and expand lift durability across all types of lift equipment.

How Everstar’s Aerial Platforms Meet Modern Demands

Everstar Machinery designs its aerial lifts with reliability and innovation at the forefront. Electric scissor lifts are ideal for warehouses and indoor spaces, while articulating and telescopic boom lifts easily handle large construction projects.

Each model offers benefits such as durable parts, precise hydraulic controls, and energy-efficient operation. Everstar equipment assists operators in completing jobs safely and efficiently, offering sustainable solutions for today’s varied work sites.

FAQ – Boom and Scissor Lifts

What is the OSHA rule for scissor lifts?

OSHA treats scissor lifts as mobile scaffolds. Operators must use guardrails, inspect hydraulics and tires, and stay within the platform. Training on safe operation and capacity limits prevents accidents or tip-overs.

Can scissor lifts reach higher than boom lifts?

No. Scissor lifts usually reach 20 to 50 feet, while boom lifts can extend up to 180 feet. Boom lifts, including telescopic and straight boom lifts, are designed for height and access, making them ideal for hard-to-reach areas.

What are the main uses for boom lifts?

Different types of boom lifts are used in construction, maintenance, and tree trimming. Their hydraulic arms allow workers to maneuver around barriers and reach elevated areas. Articulating boom lifts and telescopic boom models are both well-suited for complex outdoor jobs.

How do I decide between a scissor lift and a boom lift?

You can consider several factors such as height, load capacity, and terrain. Scissor lifts work best on stable surfaces for team operations. A boom lift is the right type for angled or elevated jobs requiring motion and reach. Assess job site layout and safety before renting or buying.

What maintenance is required for aerial lifts?

Inspect batteries, hydraulics, and platform controls daily. Follow maintenance schedules for oil changes and lubrication. Check joints and sensors regularly. Preventive maintenance keeps both scissor and boom lifts safe and expands machine life.

Conclusion: Choosing the Right Aerial Lift for Your Project

Both scissor and boom lifts are essential for safe elevated work. Scissor lifts deliver high capacity and stability for team projects, while boom lifts offer the reach and flexibility needed for hard-to-reach areas.

The main reason to choose a particular tool depends on job site conditions, terrain, and required height. Always prioritize safety, training, and maintenance to ensure reliable performance.

Consult Everstar Machinery Experts for Your Aerial Lift Selection

If you need help choosing the right aerial lift for your job site, contact Everstar Machinery. Our team can recommend the best scissor lift models, telescopic booms, or articulating boom lifts for your needs.

Request a consultation to explore durable, high-performance equipment designed for safety, efficiency, and long-term benefits.