Key Takeaways

- Understanding the boom lift reach chart ensures safe vertical and horizontal access for maintenance, construction, or cleaning without exceeding limits.

- Choosing the right telescopic boom depends on site conditions, outreach, and platform capacity to complete tasks efficiently.

- Operators must verify maximum reach and platform height to avoid overextension, maintain balance, and work safely on uneven ground or tight areas.

- Selecting the proper engine type and assessing the lift’s ability to navigate taller structures and diverse terrain guarantees stability and productivity for aerial lift projects.

Telescopic boom lifts are versatile aerial platforms that extend linearly to access high, hard-to-reach areas. Accurate interpretation of reach charts allows workers to determine vertical and horizontal limits safely, ensuring precise positioning during industrial maintenance, window washing, or construction tasks.

For maximizing vertical reach with telescopic boom lifts, diesel engines are most suitable, allowing to reach maximum platform height from 20 to 63 meters, delivering strength, stability, and extended range for challenging outdoor jobs. Electric models offer an impressive reach of 22 to 29 meters for indoor areas, combining compact design with zero emissions.

Understanding reach charts, platform capacity, and site conditions ensures operators select the correct lift for each job. Evaluating maximum load, work area, obstacles, and ground conditions supports stable operation, reduces rework, and maximizes efficiency across aerial lift projects.

Anatomy of a Telescopic Boom Lift Chart

Telescopic boom lift charts illustrate the operational envelope, showing the maximum platform height, horizontal outreach, and load capacity. Understanding these charts helps operators maintain balance, comply with safety standards, and select the correct machine for each task.

Charts typically display vertical height on one axis and horizontal reach on the other, often including color-coded zones for safe operation. Icons highlight restricted areas, overhead obstructions, or maximum load capacity, guiding operators in complex work zones and pedestrian areas.

Axes, Zones, and Symbols

The vertical axis shows the maximum platform height, while the horizontal axis displays outreach at extended or retracted boom positions. Workers must consider both together to maintain stability, reach all work area points safely, and avoid tipping hazards, collisions, or obstacles.

Color-coded zones indicate safe, cautionary, and restricted areas. Icons indicate attachments, outrigger positions, overhead hazards, and pedestrian zones, guiding efficient navigation through tight spaces, uneven terrain, or complex job sites.

Capacity Ratings and Attachments

Platform capacity changes with boom height, outreach, and added attachments. Personnel, tools, or material handling devices affect maximum load, altering safe working zones and requiring model adjustments for industrial maintenance or construction tasks.

Attachments such as baskets, hoists, or tool trays influence center of gravity, stability, and reach radius. Correctly reading these variations prevents overload, ensures safe operation, and supports full range of motion for window cleaning, maintenance, or aerial construction projects.

Using Reach Charts to Select the Right Lift

Selecting the right telescopic boom lift begins with translating jobsite requirements into measurable parameters. Reach charts help planners match maximum platform height, outreach, and capacity to tasks, terrain, and obstructions.

Translating Jobsite Requirements into Chart Points

Start by defining the task with actual site measurements—building elevations, horizontal offsets, and required up-and-over distances. These values plug directly into the reach chart, showing whether a lift can meet the required working envelope without exceeding load or extension limits.

Then account for real-world conditions, such as walls, railings, overhead structures, or uneven terrain. Mapping these constraints onto the chart pinpoints the models that maintain stability and deliver the required working arc for industrial maintenance tasks.

Matching Everstar Models to Chart Needs

To narrow down Everstar telescopic lifts, compare the required working envelope with the maximum platform height and outreach. Diesel units provide 20 to 63 meters of working height for higher elevation and longer horizontal coverage, while electric boom lifts offer 22 to 29 meters for indoor or compact areas.

Evaluate platform capacity, including personnel and tools, to confirm the lift can safely support the maximum weight. Both diesel and electric models offer 300 to 480 kg of capacity, and accurate interpretation of reach charts shows how much of that capacity remains available at specific height and outreach points.

Drive configuration affects lift selection and jobsite efficiency. Diesel lifts offer 360° continuous rotation and up to 5 km/h stowed speed for large outdoor sites, while electric lifts provide similar rotation and a 4.4–5 km/h stowed speed, optimizing movement in warehouses, pedestrian zones, or confined structures.

Engine Type: Diesel vs Electric Advantages

Everstar straight boom lifts are available with diesel or electric engines. Diesel models provide powerful performance on rough terrain, while electric lifts enable quiet, zero-emission process indoors or near sensitive areas without sacrificing reach or balance.

Telescopic vs. Articulated Boom Lifts Specifications

Telescopic boom lifts extend linearly for precise vertical and horizontal reach, while articulated boom lifts use hinged sections to maneuver around obstacles and reach over confined spaces. Choosing the right type depends on site layout, access challenges, and task requirements for safe positioning and coverage of the work area.

Understanding reach charts also highlights how boom lifts differ from other construction lift types. Scissor lifts and Ladder Lift Trucks rely on fixed vertical elevation or linear extension and do not require reach charts to define their working limits.

Field Scenarios and Common Mistakes

Real-world applications help operators interpret reach charts accurately, improving safety and efficiency. Field scenarios show how telescopic boom lifts perform in maintenance, tree trimming, and industrial construction, helping planners anticipate obstacles and prevent costly mistakes.

Examples of Correct Equipment Selection

A few practical scenarios show how reach charts help choose the right lift:

- Warehouse façade work: The reach chart identifies the required horizontal outreach to clear the façade’s setback, allowing the operator to select a telescopic boom lift with the correct working height and radius. This ensures the aerial platform stays stable and properly positioned.

- Plant shut-down access: Reach charts confirm whether a track-drive telescopic lift can maintain the needed horizontal reach at mid-height while operating on muddy terrain. These chart values guide extension limits, platform capacity, and safe elevation for accessing elevated equipment.

- Bridge maintenance: Chart data determines if a straight-line telescopic boom lift can achieve the necessary up-and-over arc to bypass guardrails and structural beams.

Frequent Errors When Reading Reach Charts

Common mistakes when interpreting reach charts can compromise safety and efficiency:

- Misreading height vs. outreach: Operators overestimate how far the boom can extend horizontally at a given vertical height, increasing the risk of collisions or instability in the work area.

- Ignoring jib articulation: Failing to account for the articulated boom’s range of motion can prevent proper positioning, reducing reach efficiency and increasing the likelihood of accidents.

- Overestimating platform capacity: Adding materials or tools beyond the rated maximum load can destabilize the platform, especially on uneven ground or near sidewalks.

- Neglecting terrain and obstacles: Failing to account for muddy terrain, construction site features, or other obstructions can lead to retraction too late, creating unsafe angles or restricting operator movement.

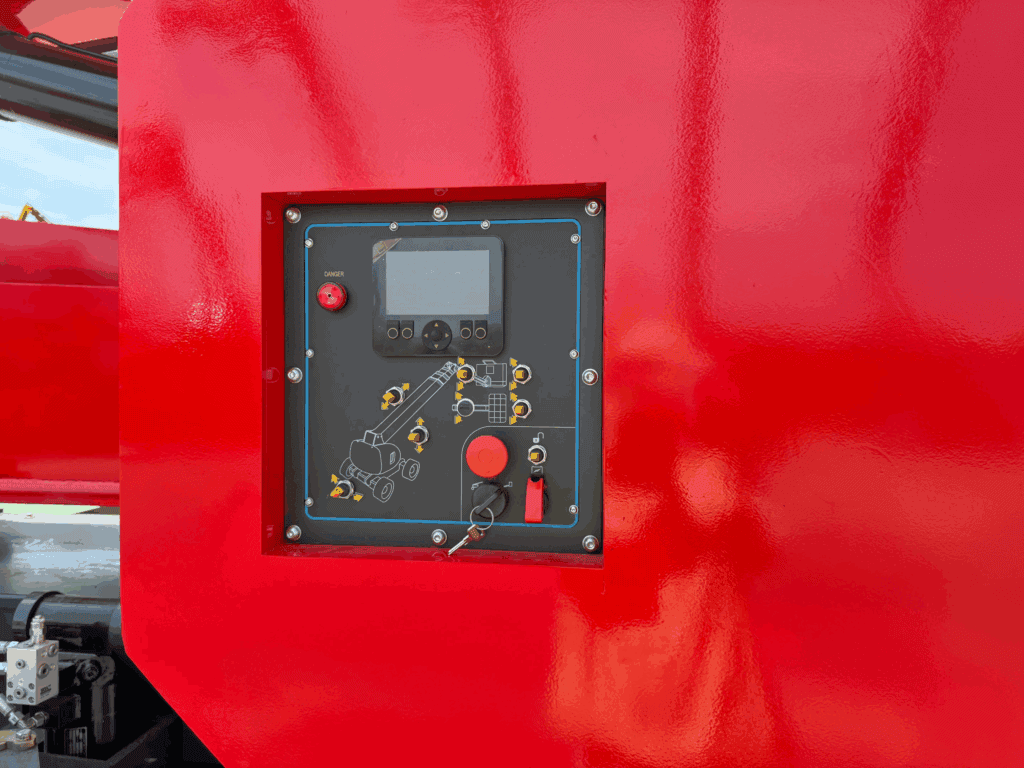

Basic Maintenance and Pre-Operation Checks

Proper maintenance of boom lifts ensures safe use and optimal reach. Inspect cylinders, joints, platform stability, and controls before process, and verify that the work area is clear of obstacles that could interfere with lift extension or positioning.

Following OSHA guidelines helps workers perform thorough pre-operation checks, adhere to safety protocols, and reduce the risk of accidents during lift procedure.

FAQs – Boom Lift Extension

How do boom lifts extend?

Telescopic boom lifts extend via hydraulic cylinders that push boom sections linearly. Operators control extension from the platform or ground, allowing precise vertical and horizontal positioning for window cleaning, maintenance tasks, or construction work safely.

What happens if my required reach is just beyond the chart limit?

Exceeding the chart’s maximum platform height or outreach requires selecting a different lift model or adjusting the job. Attempting to extend beyond limits risks instability, tip-over, or equipment failure, compromising safety and efficiency on site.

Do attachments change the allowable reach and capacity?

Yes, material handling or tool attachments affect the aerial platform’s maximum weight and working envelope. Reach charts reflect these changes, and operators must account for added loads to ensure balance, safe operation, and adherence to Everstar safety standards.

Conclusion: Choosing the Right Telescopic Boom Lift Through Reach Chart Mastery

Reach chart mastery allows operators to identify the telescopic boom lift that meets specific height, outreach, and site requirements. Understanding chart data ensures proper positioning, prevents overextension, and guides safe operation in construction, maintenance, or tight work zones.

Accurate chart interpretation also helps assess platform capacity and site obstacles. This knowledge ensures operators select the lift that provides optimal stability, efficient reach, and effective task completion across diverse maintenance and construction scenarios.

Speak with Everstar About Boom Lift Reach Planning

Contact Everstar Machinery to interpret reach charts and match telescopic boom lifts to project needs. Explore full specifications, model options, and attachments to maximize reach, maintain stability, and complete tasks efficiently, including safe transport and fully engineered operation.